Machining Capabilities

Equipped with state-of-the-art machinery and a skilled workforce, we ensure precision and efficiency in every component we produce.

Machining Capabilities

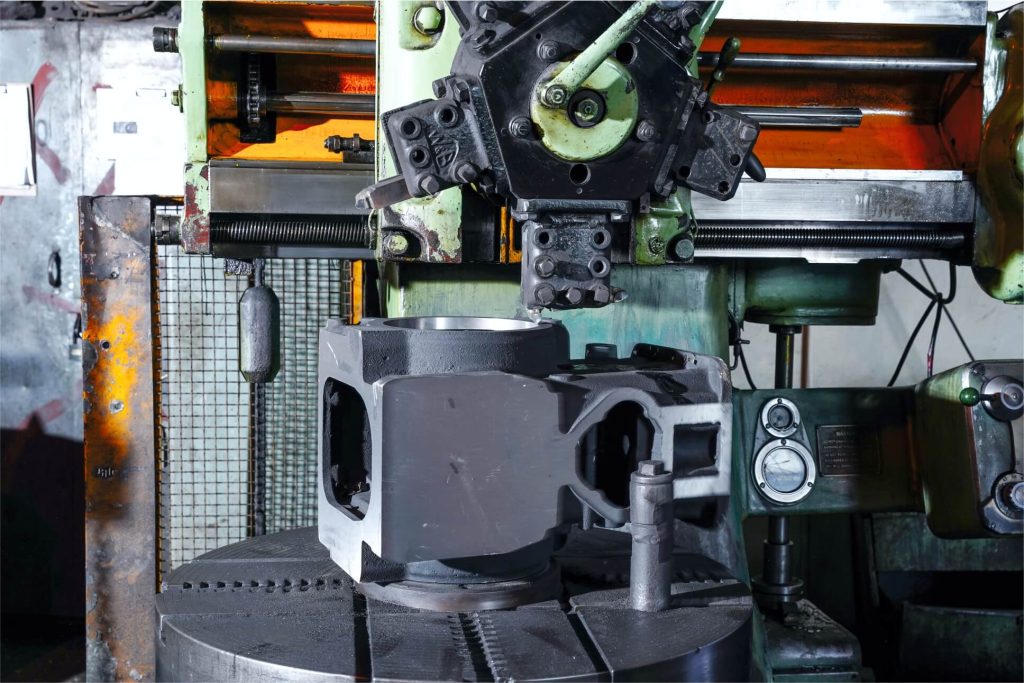

Madina Auto Industries (MAI) offers advanced machining services to complement its casting expertise. Equipped with state-of-the-art machinery and a skilled workforce, we ensure precision and efficiency in every component we produce.

Capabilities:

CNC and conventional machining

Precision drilling, turning, milling, and grinding

Custom machining for complex geometries

Focus on Quality:

Strict adherence to dimensional accuracy

Advanced inspection tools for quality assurance

Applications:

Machined components for automotive and tractor industries

Our machining processes are designed to deliver high-performance parts that meet the exact specifications of our customers, ensuring reliability and durability in every product.

Drilling:

High-precision drilling for accurate hole placement and sizing

Capability to handle complex drilling patterns for customized components. Advanced equipment to ensure consistency and quality.

Other Processes:

Turning:

Precision turning for creating cylindrical components with exact dimensions.

Milling:

High-efficiency milling for intricate shapes, slots, and surfaces.

Grinding:

Surface and cylindrical grinding for achieving fine finishes and tight tolerances.

Tapping:

Accurate threading for various applications.

Finishing:

Deburring and surface treatments to enhance durability and appearance.

By integrating these processes with our casting expertise, MAI delivers complete manufacturing solutions, ensuring top-notch quality and performance in every product.